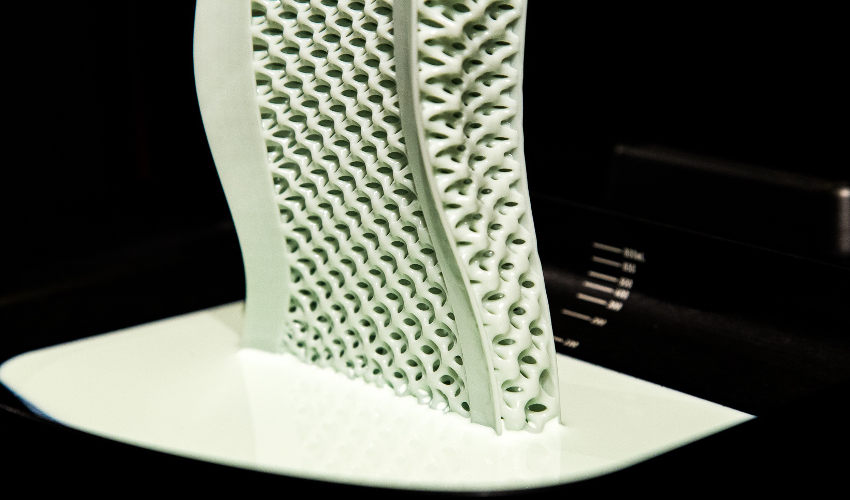

We demonstrate how this modified printer can be combined with various design strategies to achieve high levels of complexity and versatility in the 3D-to-3D shape-shifting behavior of our reconfigurable materials and devices. This simple modification allows the printer to print on curved surfaces. Here, we present a single-step production method for the fabrication and programming of 3D-to-3D shape-changing materials, which requires nothing more than a simple modification of widely available fused deposition modeling (FDM) printers. That is caused by the intrinsically 2D nature of the layer-by-layer manner of fabrication, which limits the possible shape-shifting modes of 4D printed reconfigurable materials. As compared with the 4D printing of 2D-to-3D shape-shifting materials, the 4D printing of reconfigurable (i.e., 3D-to-3D shape-shifting) materials remains challenging. Upon activation, not only a change in their shape but also a large shift in their material properties can be realized. N2 - Shape-shifting materials are a powerful tool for the fabrication of reconfigurable materials. T1 - 4D printing of reconfigurable metamaterials and devices We showcase the potential of the proposed approach for the fabrication of deployable medical devices including deployable bifurcation stents that are otherwise extremely challenging to create.",

We showcase the potential of the proposed approach for the fabrication of deployable medical devices including deployable bifurcation stents that are otherwise extremely challenging to create.Ībstract = "Shape-shifting materials are a powerful tool for the fabrication of reconfigurable materials.

Shape-shifting materials are a powerful tool for the fabrication of reconfigurable materials.

0 kommentar(er)

0 kommentar(er)